A team of Pennsylvania State University researchers has developed a new process for making perovskite devicesIt is also more efficient from an economic point of view in terms of the time required for the process to take place.

Thanks to that, it will also be possible to find new products in the future in a relatively quick way.

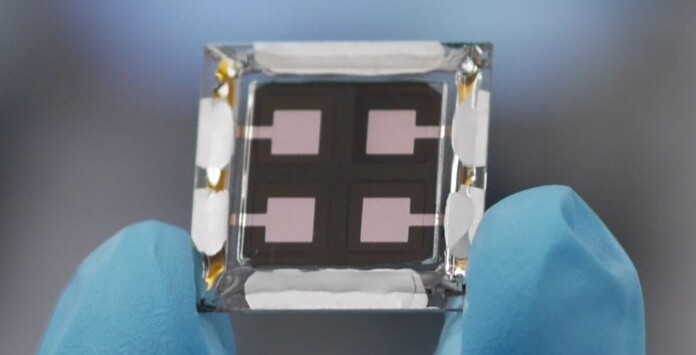

Produce the next generation of photovoltaic solar cells

The secret lies in plasma spark sintering. (A Sintering (The powders, with or without crystallization once compacted, are subjected to high temperatures, slightly below their melting temperature).

Named EM-FAST or, in current parlance, plasma spark sintering, the technique applies electric current and pressure to powders with the aim of obtaining new materials.

Regardless of the raw material used, the yield was always 100%, in contrast to the very poor results obtained with solution-based processing, where it ranged from 20 to 30%.

Using this technique, they were able to produce perovskite materials at a speed of 0.2 inches per minute, contributing to the rapid creation of large devices capable of maintaining high efficiency in laboratory tests carried out by the research team.

In the words of leading author Luao Zheng of this study, “The method we developed allows us to easily create large bulk samples in minutes, rather than taking days or weeks with traditional methods.”

EM-FAST technique in detail

The English acronym EM-FAST stands for Electric and Mechanical Field-Assisted Sintering Technique, and as already mentioned, this is the technique used to create the perovskite devices in question, which can then be used in the production of photovoltaic solar cells.

Sintering is widely used, for example, to compress and transform powdered materials to obtain solid masses by applying heat and pressure.

The problem is that even using materials perfectly suited to the process in question, it is inefficient when the intention is to create large pieces of perovskite, not to mention that the solvents used are often toxic.

“Our technique brings the best of both worlds: we get properties similar to single crystals, and we don’t have to worry about size limitations or any contamination or production of toxic substances”, Bette Bowdell, a research professor at Pennsylvania State University and co-author of the study.

As it uses dry ingredients, the EM-FAST technique creates the possibility of adding new ingredients, customized according to the properties obtained from the final result.

In this way, we have an open door to develop new materials, including thermoelectric and solar.

Additionally, this process allows powders to be arranged in different layers, leading to the possibility of creating customized devices on demand in the future.

“Hardcore explorer. Extreme communicator. Professional writer. General music practitioner. Prone to fits of apathy.”